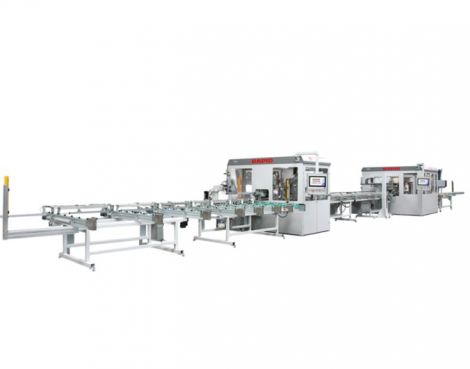

Optima VIA - Cutting & Processing Centre

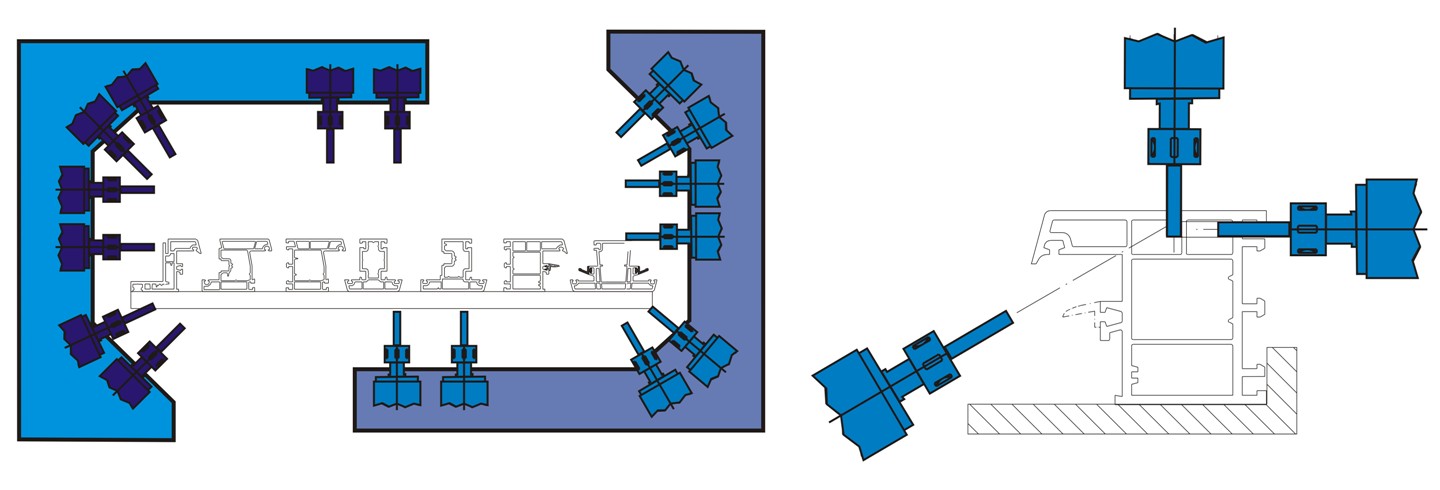

Flexible installation concepts

The key feature of RAPID-manufacturing concept for the Optima VI / VIA is the consistently implemented modular construction. By separating and therefore the independence of the saw unit and processing module significant increases of capacity are possible. The arranged buffer station between the two modules makes a decisive contribution.

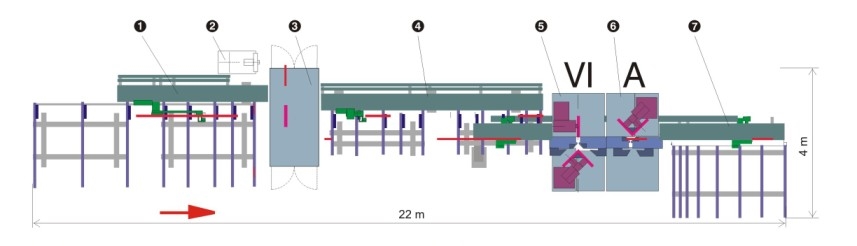

System features:

- In feed magazine for a maximum profile length of 6500 mm

- Extraction

- M-Module

- Buffer station

- VI-saw module

- A-saw module

- Off transport via VA-table or belt system

- CNC-Control with windows user interface

- Safety fence including doors and emergency stop connection

Suitable for:

- PVC

Very fast and most accurate PVC-U cutting and processing

Cutting centre Optima VIA

Through the V-layout of the saw achieves shorter working cycles for 45°cuts than with ordinary saw layouts. Feed and advance motions via servo axes increase the cutting speed and quality. The A-saw (option) allows additional operations such as arrow heads, bevel cut or V-notch cut on both sides.

Processing M-Module

At the M-Module begins the processing of the bars. After every milling is done, the gripper moves the profile to the buffer magazine (option), which transports the profile to the cutting module Optima VI.

Snij- en bewerkingscentra - Centre debitare si prelucrare PVC - Centra obróbcze oraz tnące - Skär- och bearbetningscentra - Centros de corte y mecanizado

Cut variants Optima VIA

| Saw motor Optima VI | 45° saw: 4 KW 90° saw: 1.85 kW |

|---|---|

| Saw blade | 45° saw: 500 mm diameter 90° saw: 450 mm diameter |

| M-Module standard configuration | Milling units 0.27 kW / 1.1 kW |

Cutting centre VI/A

Through the V-layout of the saw achieves shorter working cycles for 45°cuts than with ordinary saw layouts. Feed and advance motions via servo axes increase the cutting speed and quality.

Standard operations Optima VI:

- 90° cut at both sides

- A combined cut with 45° and 90°

- 45° cut at both sides

- Bevel cut

- V-notch cut

Optional operations

(Optima VIA by using of the A-Saw):

- Arrow heads on both sides

- Bevel cut on both sides

- V-notch cut on both sides

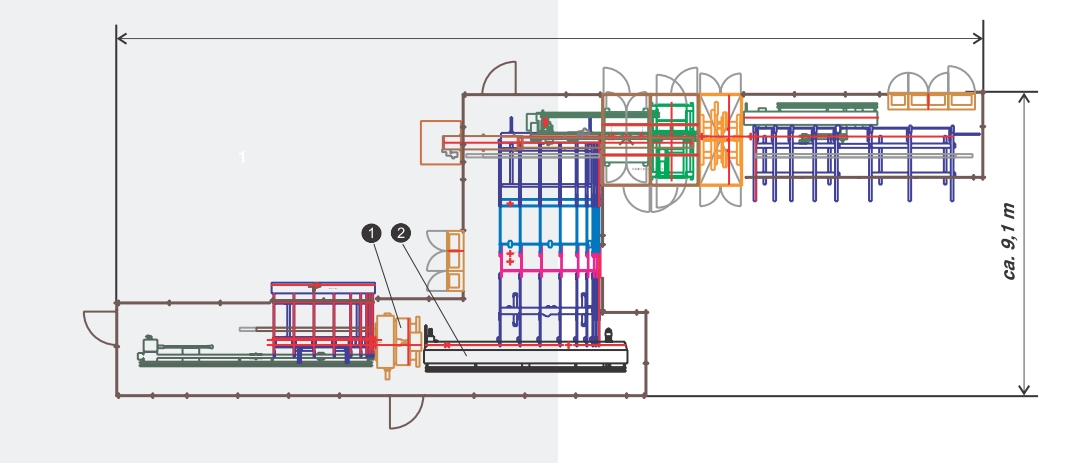

M-Modul

PVC processing before cutting

With the M-Module begins the processing of the bars. After every operation is done, the gripper moves the profile to the buffer magazine (option), which transports the profile to the cutting module Optima VI. Every part has the RAPID quality guarantee, from a solid basic frame, operator friendly controle to complete production lines - we build reliable, powerfull machines

Standard operations:

- Drainages and pressure equalisations

- Handle holes

- Lock house slots and millings

- Marks for hinges

- Marks for locks

- Night vents

- Fixing holes and millings

- Transom holes for mechanical joints

Door operations (optional):

- The option “interpolated axis” allows all standard door operations

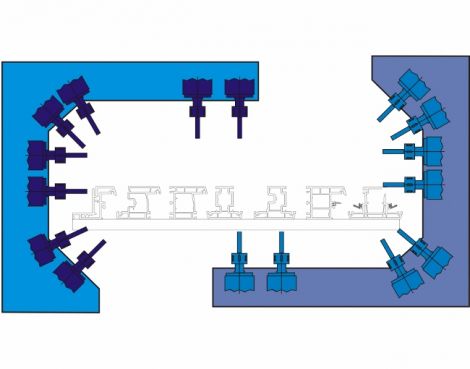

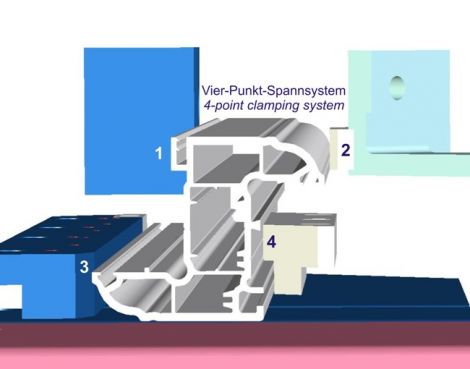

System Features

- Extrem solid maschine bed, guides and spindles

guarantee a long life cycle - Optimum profile clamping by two side support

- Profile support is hard coated or maid from stainless

steel, with integral blowers for self cleaning - Solid vibration free machine base for the mounting of

all milling units - Configuration up to 16 milling tools

6 axis M-Module:

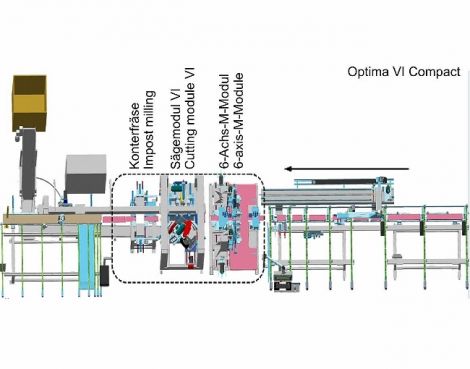

Layout Optima VI/A with M-Modul and buffer station

- In feed magazine for a maximum profile length of 6500 mm

- Extraction

- M-Module

- Buffer station

- VI-saw centre

- A-saw centre

- Off transport via VA-table or belt system

Layout Optima VIA Compact with M-Modul combined with SBC

- External screwing station on a separate axis, inclusive gripper (option: SBC 115M)

- Milling and drilling module SBC