MFC Evolution - Machining centre

Highly flexible and universally applicable for processing of PVC profiles with or without reinforcement. Proven RAPID machine building quality in connection with modern and sophisticated control technology.

Absolute accuracy of machining

- Extreme solid maschine bed, guides and spindles guarantee a long life cycle

- 360 degree technology

- The rotation device principle enables tool positioning independent for the angle

- Configuration up to 8 milling and drilling tools arbitrary

- Door-profile processing is possible with standard tools

- Automatically feeding system of the screwing unit

System features:

- In feed magazine for 10 PVC profiles

- External screwing station on a separate axis, inclusive gripper (option: MFC II)

- Milling and drilling module MFC with aggregates which are placed on a ring

- Off transport

- Out feed axis

- Scanner

Suitable for:

- PVC

| Profile dimensions | Maximum width 125 mm Maximum height 130 mm All common door and window-profiles can be processed |

|---|---|

| Piece length | Minimum inside dimension: 200 mm Maximum outside dimension, regarding to the safety fences dimension: 3500 mm |

| Standard configuration: | 6 drilling units 0,75 kW 2 milling units 2,2 kW |

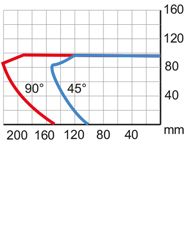

Schnittdiagramm (Kopie)

MFC I

with an internal screwdriver

MFC II

with an external screwdriver

The screwdriver unit fixes the reinforcement, and moves the piece to the take over position of the milling unit. The process of machining and of the next piece works in parallel. Thereby the productivity can be increased considerable

Snij- en bewerkingscentra - Centre debitare si prelucrare PVC - Centra obróbcze oraz tnące - Skär- och bearbetningscentra - Centros de corte y mecanizado