Optima Evolution - Cutting center

Flexible installation concepts

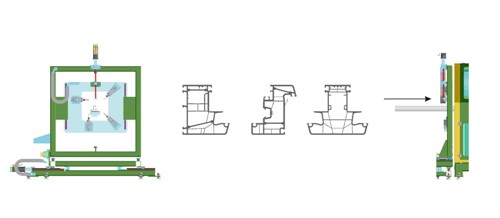

With this sub bench saw all requirements are fulfilled that are assumed by the automatic PVC machining. This solution is available as stand-alone machine as well as in combination with the profile processing centre MFC Evolution. Through this flexible concept new possibilities arise.

Standard operations:

- 90° cut at both sides

- A combined cut with 45° and 90°

- 45° cut at both sides

- Intermediate angles (Option)

Optional operations:

- Bevel cut

- Arrow cut

System features:

- In feed magazine for 10 PVC profiles

- Cutting bottom-up unit with an adjustable saw blade angle 45°/90°/135°

- Intermediate angles

- Off transport via VA-table or belt system

- Label printer

- Waste conveyor belt

- CNC-Control with windows user interface

- Extraction

- In feed for a maximum profile length of 6500 mm

- Safety fence including doors and emergency stop connection

Suitable for:

- PVC

RAPID Optima Evolution MS - sawing and processing center for plastic profiles in window production

The RAPID Optima Evolution cutting center can optionally be equipped with an MS module, a milling station for drainage, ventilation and similar processing in PVC window profiles. See the YouTube Video Optima MS Evolution.

All machining is done on the entire bar before cutting. Feed magazine is designed for 10 profiles, material feed for a maximum profile length of 6500 mm. Integrated measuring systems automatically check the profile length and width, then the bar is first transported to the processing position.

The MS module is equipped with 4 milling units. The alignment of the units is adjusted to the desired processing in consultation with the customer.

After processing, the profile is transported to the under-table saw, where 45°-90°-135° cuts are made. Intermediate angles are also optionally possible.

Cut parts can then be labeled on the take-off table or belt conveyor.

After the steel has been inserted, the remaining processing can be carried out in the RAPID MFC Evolution machining center. The integrated or upstream automatic screwdriver screws the reinforcement profiles to the plastic profile (detailed videos on our channel: YouTube Video RAPID MFCII Evolution and YouTube Video MFC II - External screwdriver).

All steel and PVC processing is then carried out in the ring module using wireless 360° technology. The slewing ring principle enables the angle-independent positioning of up to 8 drilling and milling tools. Through the processing optimization between the MS module of the Optima Evolution and the MFC Evolution machining center, the capacity of the entire production line can increase by approximately 30%.

| Drive | 2,2 KW with a mechanical brake |

|---|---|

| Profile dimensions | Maximum width 125 mm Maximum height 130 mm All common door and window-profiles can be processed |

| Piece length | Minimum inside dimension: 200 mm Maximum outside dimension, regarding to the safety fences dimension: 3500 mm |

| Saw blade | 500mm |

Milling station MS-Module - 4 milling units 0,27 kW

Die The Milling Station MS-Modulecan be installed on the cutting centre Optima Evolution. The machining operations take place in the hole profile bar before cutting. This discharges the machining centre MFC Evolution which follows after reinforcing. The optimisation of the machining operations increases the capacity of the production line Ultratech of approx. 30%.